Godfrey & Wing Partners with Cee Dee Vacuum Equipment in India

Godfrey & Wing recently expanded their international presence as they launched a partnership with Cee Dee Vacuum Equipment in India, a leading manufacturer of vacuum impregnation equipment for dry type transformers and porous castings. Cee Dee has extensive experience in the design and manufacture of front load and top load vacuum and pressure impregnation […]

Read MoreGodfrey & Wing Partners with Tecnocomponenti in Italy

Godfrey & Wing recently expanded their international presence as they launched a partnership with Tecnocomponenti Ltd. in Tuscany Italy, a highly specialized job shop operating two vacuum impregnation lines using anaerobic sealant.

Read MoreGW’s Vacuum Impregnation Expertise Featured in Die Casting Engineer

Godfrey & Wing recently published two articles in Die Casting Engineer, the official publication of The North American Die Casting Association. These articles are intended to educate people about vacuum impregnation basics and processes. The first article in the November 2012 issue featured the basics of vacuum impregnation, and the second article in the January […]

Read MoreVacuum Impregnation Technology Presented

Godfrey & Wing GmbH showcased their vacuum impregnation equipment and sealant technology at the Trends in Engine Technology Symposium on November 7, 2012 in Passau Germany. The purpose of the symposium was to present the latest engine technology. Presentations were made by Audi, BMW, Continental, MAN, Porsch and Schaeffler. Godfrey & Wing exhibited their […]

Read MoreLean Vacuum Impregnation System Benefits Automotive OEM

A new, lean vacuum impregnation system is providing significant economic benefits for a Japanese automotive OEM in the USA. The Continuous Flow Impregnation (CFi) system, from Godfrey & Wing, has been installed as part of a fully automated engine manufacturing line and is capable of impregnating a single aluminum cylinder block in less than 98 […]

Read MoreGodfrey & Wing’s Versmold Publishes Articles on Vacuum Impregnation

Ralf Versmold, Managing Director of Godfrey & Wing GmbH, recently published three articles on vacuum impregnation in the German publication Giesserei Praxis. This series of articles is intended to educate people about vacuum impregnation processes, equipment and sealants. The first article in the March issue featured the basics of vacuum impregnation; the second article in […]

Read MoreGodfrey & Wing Sponsors Aurora Robotics First Lego League

Godfrey & Wing, located in Aurora, is sponsoring the Aurora Robotics First Lego League, an exciting and fun robotics program that ignites an enthusiasm for science, technology, engineering and math in children ages 9-14. Every year a new challenge theme is given to all Lego League teams to compete with each other. The students research […]

Read MoreLarge Foundry Technology Conference in Salzburg

Godfrey & Wing GmbH will showcase their vacuum impregnation processes, sealants and equipment at the “Große Gießereitechnische Tagung” (GGT) in Salzburg Austria April 26-27. Foundrymen from Germany, Austria and Switzerland are expected to attend. Visit Godfrey & Wing’s booth to learn more about the latest innovations in vacuum impregnation, including our High Value / Low […]

Read MoreNew Solution for Casting Impregnation with HVLV Impregnation System

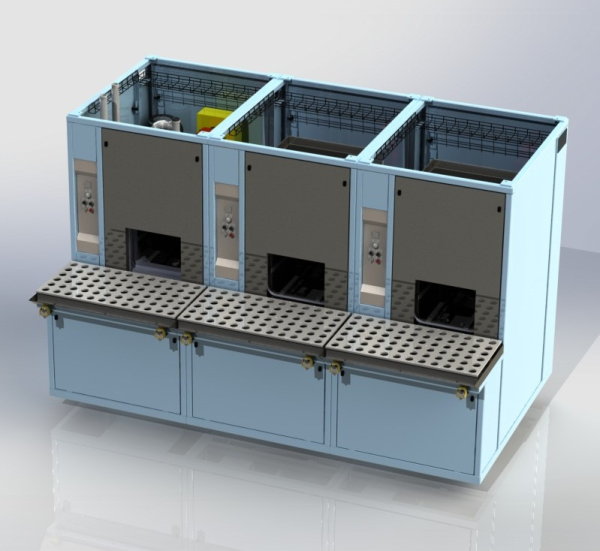

This latest innovation in vacuum impregnation provides state-of-the-art impregnation technology in the smallest possible footprint and at a capital cost that makes impregnation affordable for any OEM or manufacturer. The High Value / Low Volume (HVLV) system utilizes Dry Vacuum and Pressure processing (DVP), the most robust impregnation process available, and is capable of processing […]

Read MoreGodfrey & Wing Donates Sealant to Villanova’s Formula SAE Team

Godfrey & Wing recently donated some of their 95-1000A thermal curing sealant to Villanova’s Formula SAE Team. Formula SAE is a student design competition organized by the Society of Automotive Engineers. Students are challenged to conceptualize, design, fabricate, and compete with a formula-style racecar. The team used Godfrey & Wing’s 95-1000A sealant in the process […]

Read More