How to Eliminate Sealant Contamination

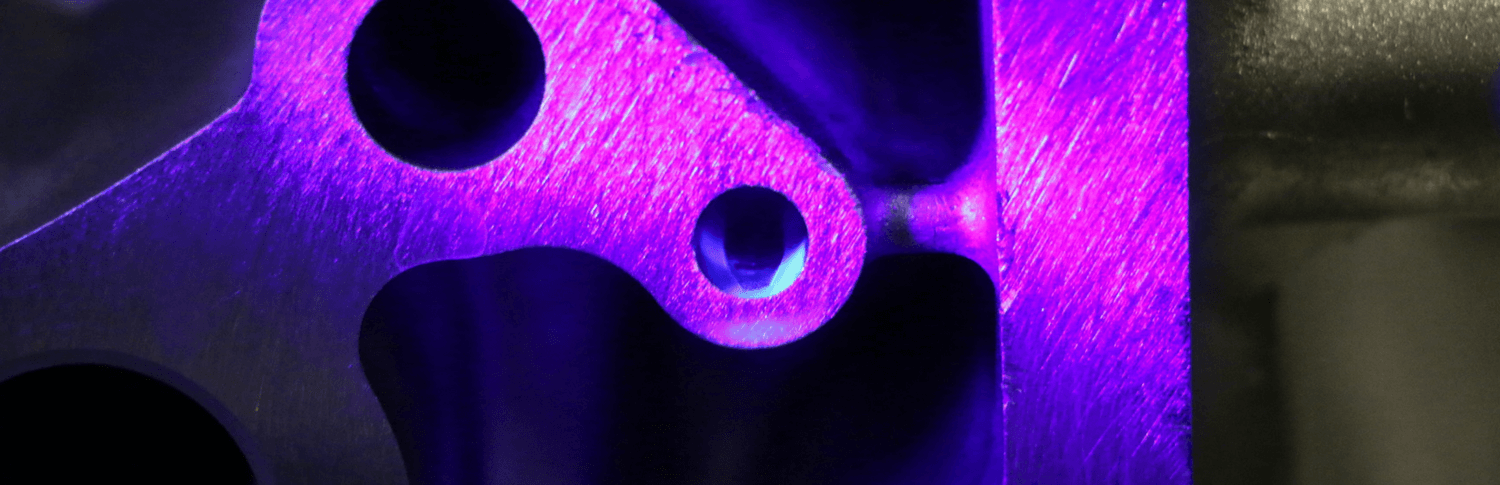

A common frustration we hear from manufacturers is that their vacuum impregnation process may seal porosity, but some parts still need to be scrapped due to sealant contamination (Image 1). Most of these manufacturers assume this is normal. The fact is that this is not normal, nor should it be accepted as a typical outcome of the vacuum impregnation process.

Image 1: This feature has excess sealant. The excess sealant will cause quality and assembly issues.

Why is Sealant Contamination a Problem?

There are a number of reasons why sealant contamination is a problem. Excess cured sealant can affect assembly and part quality. Cured sealant found in tapped holes or blind passages can cause assembly issues or prevent fluid flow in oil passages or water channels. Excess cured sealant on a part’s surface can affect secondary operations, such as painting, plating, or machining. Nonfunctional parts are unusable and must be rejected.

How is Sealant Contamination Caused?

During the impregnation process, uncured, liquid sealant is drawn in the part’s porosity. Residual sealant can also remain in openings such as oil passages and water channels. This is not a problem, as long as the sealant is properly washed from those openings. If that wash does not happen, or it is inadequate, the sealant will cure to a hard polymer and cause problems in those areas of the casting.

The root cause of this contamination may be one, or a combination, of these failure modes:

- Poor Sealant ControlSealant control is typically the least impactful failure mode and is often easy to correct. A common occurrence is that a sealant’s chemistry may change, affecting its sealing properties. Excess sealant chemicals are carried into the wash and cure, prohibiting the parts from being properly cleaned and cured.

- Inadequate Process ParametersInadequate process parameters are deviations outside an acceptable process range or parameters that lack the proper steps. Examples include an operator layering parts incorrectly so that features are masked and cannot get thoroughly washed; or water in the wash module not being drained or regulated after use, so water laden with sealant from previous cycles will cause future contamination.

- Equipment Design Issues Equipment design issues are the most prohibitive to change. Once the equipment is purchased, changes to its design may be impossible. Examples of equipment design issues include the lack of a centrifuge to remove and recover excess sealant before the wash, or a wash module that passively washes while leaving sealant on parts.

How To Eliminate Sealant Contamination?

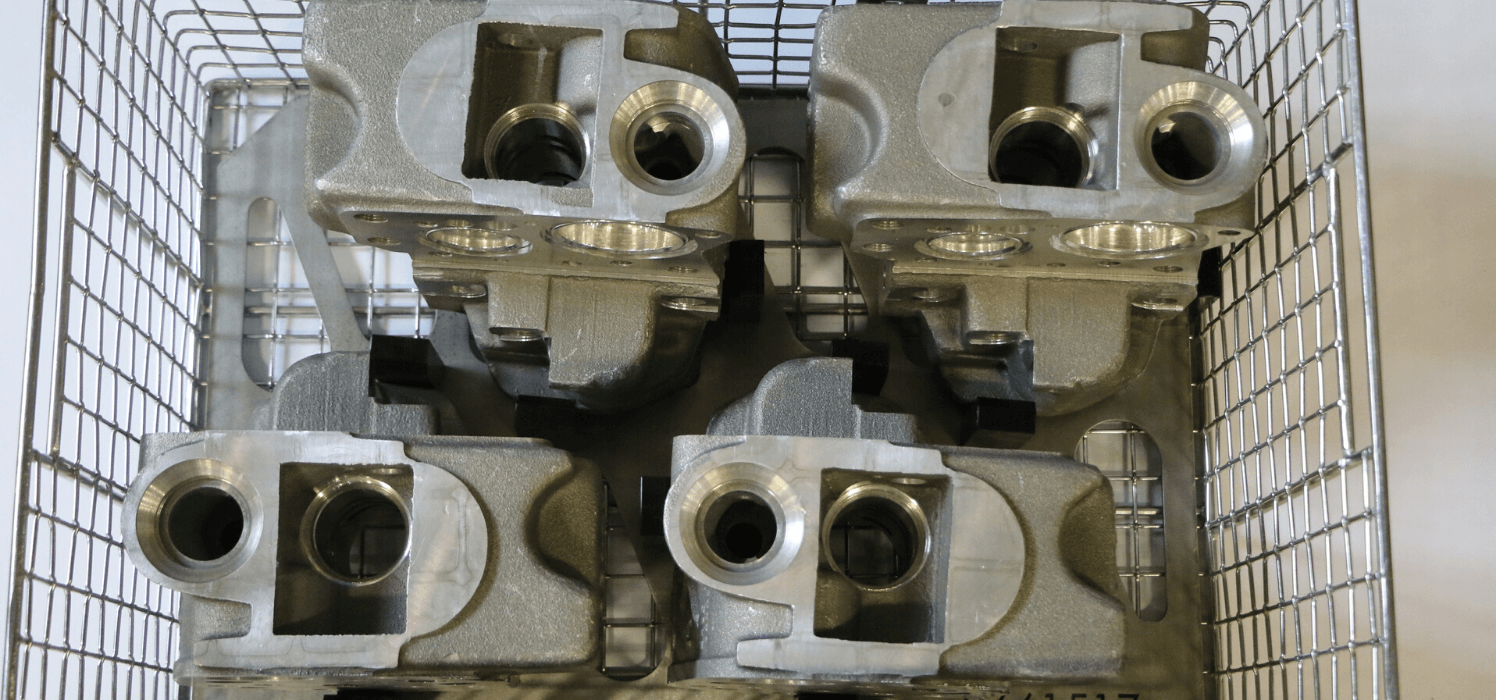

To eliminate sealant contamination, one first must determine its cause. For an existing program, a manufacturer should review sealant control, then process parameters, and finally equipment capability (Image 2).

Image 2: Proper fixturing enables sealant to be properly washed from machined features.

For a new vacuum impregnation program, one must be aware of the requirements of the parts to be processed. Each program should be evaluated for equipment, sealant, and process as no two programs are the same.

For example, a manufacturer should not use the same process to seal macro-porosity in powder metal as for micro-porosity in aluminum die casting. The powder metal process uses just a passive wash; a more aggressive wash is needed to remove the sealant from small features in the aluminum casting and decrease the risk of contamination.

Conclusion

This simplified blog provides a better understanding of sealant contamination. It’s a starting place to look for the root cause and identify how to correct it. Sealant contamination does not have to be accepted. By eliminating it, manufacturers can maximize their number of parts in production.