Motor Controls Manufacturer Installs Impregnation System for In-House Production

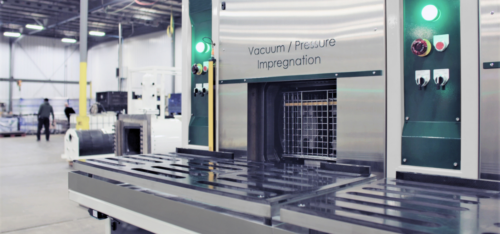

Foundry Management & Technology recently wrote an article about a Godfrey & Wing HVLV vacuum impregnation system that was installed at SEW-Eurodrive. You can read the entire article below. Sealing equipment specialist Godfrey & Wing has a contract to supply its HVLV vacuum-impregnation system to SEW-Eurodrive, to seal diecast aluminum motor and gear components at […]

Article: Vacuum Impregnation Enables Lightweight Material Use

Godfrey & Wing has published an article in LightWeighting World titled “Vacuum Impregnation Enables Lightweight Material Use”. This article discusses the surge in aluminum use and how vacuum impregnation eliminates aluminum casting porosity. You can read the entire article below. Recent decades have seen a surge in use of aluminum castings in car manufacturing. Aluminum has […]

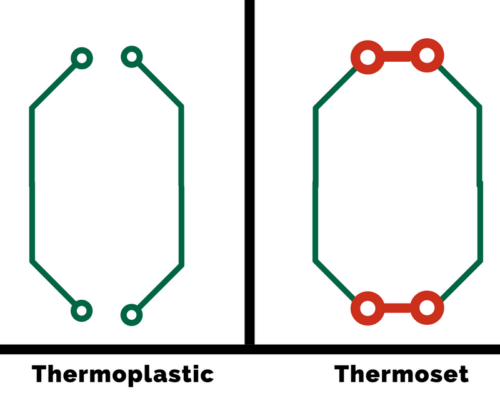

Do Vacuum Impregnation Sealants Melt?

A question that is often asked is “Will the sealant used in vacuum impregnation melt?” This is asked by those who’s castings need to withstand heat. In this blog, we will answer this question. The short answer is no, Godfrey & Wing sealants do not melt under standard operating temperatures. Impregnation sealants are based on […]

Types of Vacuum Impregnation Processes

Vacuum impregnation in metal castings and powdered metal parts refers to the sealing of leaks resulting from porosity. In this post, we will discuss in detail one of the selection variables, the three different types of vacuum impregnation processes.

Continuing Advances in Vacuum Impregnation Systems

Godfrey & Wing has published an article in Foundry Management & Technology titled “Continuing Advances in Vacuum Impregnation Systems”. This article discusses the manufacturing safety and manufacturing production advancements in vacuum impregnation equipment. You can read the entire article below.

Video: How Godfrey & Wing’s Equipment Works

Godfrey & Wing’s vacuum impregnation equipment is the best in the world. The equipment re-imagined vacuum impregnation by making it safer, increasing production and eliminating casting defects. But how exactly does it work? Watch this animation video.

Understanding the Vacuum Impregnation Process

Vacuum impregnation seals porosity and leak paths in metal castings and powdered metal parts that form during the casting or molding process. The process is done by filling the pores with a sealant under pressure to stop fluids or gases from leaking under pressure. Vacuum impregnation stops casting porosity and allows manufacturers to use parts […]

Why Use Dry Vacuum Pressure Impregnation?

To say that all vacuum impregnation processes are equal would be to say that every die casting process is the same. Nothing could be further from the truth. The vacuum impregnation process will have a direct impact on the sealing quality.

Porosity Classification System Helps Determine Solutions to Casting Leaks

Water, as we all learned in basic chemistry, exhibits a unique phenomenon: as it solidifies, it expands. For other liquids in our physical world, solidification results in just the opposite: shrinkage.

How Impregnation Makes Porous Castings Pressure Tight

Ever since metal casting was first discovered, casting porosity, an area of sponge-like internal structure in an otherwise sound metal part, has been a problem. Porous castings may be caused by internal shrinkage, gas cavitation, oxide films,inclusions and combinations thereof. It can be found in virtually any type of metal casting or part, and is […]