Godfrey & Wing Develops Technology to Seal Graphite Leak Paths in Hydrogen Fuel Cells

Godfrey & Wing, a leading global manufacturer of vacuum impregnation technology, has received a contract for an Advanced Graphite Impregnation (AGI) system from a hydrogen fuel cell manufacturer. Starting in 2023, the system will seal leak paths in bi-polar plates in fuel cell stacks for fuel cell vehicles (FCV). The AGI is designed from Godfrey […]

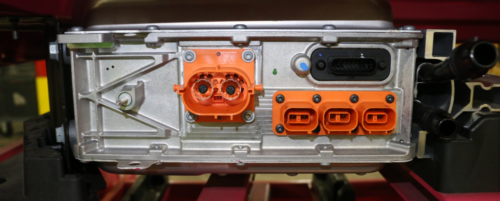

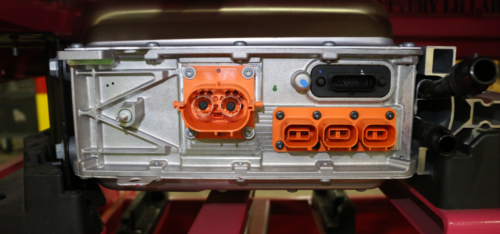

Case Study: Ensuring EV Battery Performance with Vacuum Impregnation

It is expected that there will be 134 electric vehicle (EV) car models available by 2024. Both well-established industry leaders and startups are debuting new car models and redesigning well-known models to be EVs

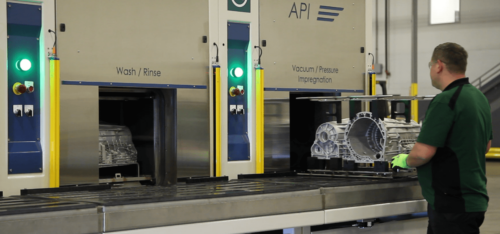

Preparing Parts for Vacuum Impregnation

When it comes to vacuum impregnation, it’s essential to ensure that the parts being impregnated are dry beforehand. This is because any surface impurities can interfere with the impregnation process, leading to subpar results.

Understanding How Vacuum Pressure Impregnation (VPI) Works

Vacuum Pressure Impregnation (VPI) is a method to insulate wound electro-mechanical parts thoroughly with a resin or varnish. VPI is a critical process to insulate and seal the porosity of the parts.

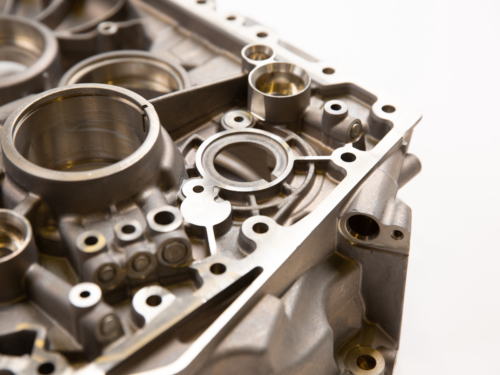

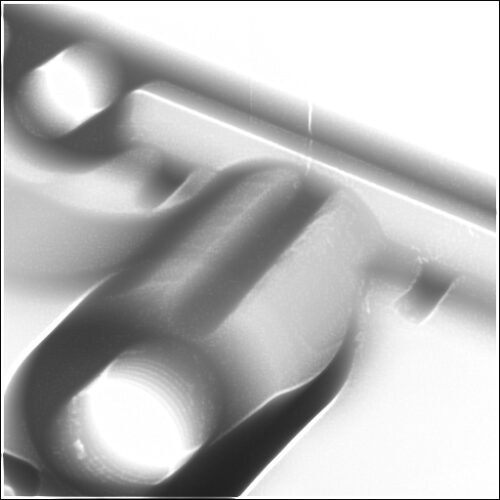

Inspect Casting Porosity with Nondestructive X-Ray

The phrase aluminum die casting porosity is used extensively when talking about any void in an aluminum casting, but it does not describe the actual problem. It can take many different shapes and forms, but it is often described just as “porosity”.

Sealing Motors with Vacuum Pressure Impregnation vs. Varnish Dip

One component that engineers are designing in electric vehicles (EVs) is the electric motor. This component is one of the main driving-forces behind EVs. Per IDTEchEx, over 100 million electric motors will be required by 2032.

Three Reasons to Seal Electronics with Vacuum Impregnation

Electronics play a crucial role in electric vehicles (EVs). In 2000 automobile electronics were responsible for 18 percent of the cost of a car. Twenty years later, electronics accounted for 40 percent of a car’s cost.

The Ultimate Guide to Sealing 3D Printed Parts

When 3D printing was first developed in the 1980’s, it was primarily used for a product’s proof of concept or initial prototypes. The limits of the technology and material did not allow one to use the process for field testing, or production.

Case Study: Tailored Solution to Seal Powder Metal Porosity

The increased use of turbochargers has become an important trend in car manufacturing. This trend has been driven by requirements to design smaller, more powerful engines that also reduce fuel consumption.

How Vacuum Impregnation Enables Lightweighting

Recent decades have seen a surge in the use of aluminum castings in car manufacturing. Aluminum has been a critical material in car manufacturing since the beginning. The first sports car featuring an aluminum body was unveiled at the Berlin International Motor Show in 1899. Carl Benz developed the first engine with aluminum parts two […]